FMS line for automotive seating (van) divided into 4 independent zones.

GENERAL INFORMATION

- Product to convey:

- Automotive seats (van)

- Weight of the seat + WPC = 80 kg

- Dimensions of the WPCt: 700 x 700 mm

- Time cycle of the installation: 60 seconds

CONVEYOR SYSTEM

- FMS Accumulation roller chain conveyor, light series: Model NT 820 26

- Upper conveyor: working line

- Lower conveyor: Empty pallet return line.

- Lifting and index station: Model NT 850 10

- Pallet rotation table:. Model NT 850 15

- Pneumatic pallet lifters: Model NT 600 40

- Working station with height regulation for ergonomics: +/- 200 mm

- Working station: LED lighting, 220V plugs, RJ45, etc.

- Rework station.

- PULL TESTER station.

ELECTRIC CABINET

- General main cabinet

- PULL TESTER electric cabinet.

- Safety PLC programming

- Frecuency inverter for gearmotors

- HMI 12″ TOUCH SCREEN

ELECTRIC FIELD INSTALLATION

- Photocells, magnetic detectors, inductive detectors, etc.

- Signal distribution units.

- Field bus: PROFINET

INSTALACIÓN DE CAMPO NEUMÁTICA

- Pneumatic stoppers with and without dumping.

- Valve manifolds

- FRL – Air maintance group

- Field bus: PROFINET

RFID

- RFID for pallet and product trazability.

- TAG for the 40 pallets.

- Signal distribution units.

SERVICES

- Mechanical and electrical desing, installation and programming.

- Comunications with: oven, client IT system and main line.

- Installation, testing and commissioning at the client facilities.

- Staff formation: GAP leaders and operators.

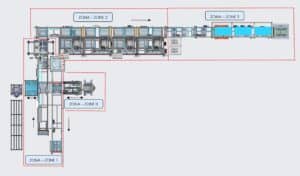

LAYOUT

- Zone 0: Pallet exchange system Switch seat from main line pallet to EOL line pallet.

- Zone 1: Wiring station, rework and PULL TESTER.

- Zone 2: Electric wiring stations – 4 units

- Zone 3: Oven, ironing, final inspection and quality.

Layout

Z.1 – Cableado / Wiring

Z. 1 Cableado / Wiring

Z. 1 – PULL TESTER

Z. 2 – E CHECK stations

Z. 2 – E CHECK stations (back)

Z. 2 – Horno / Oven

Z. 3 – Puestos finales / Working stations