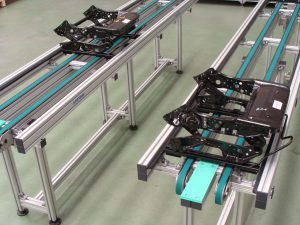

Our NT 400 family consists of several simple or double conveyor systems that can be of timing belts or chain. Depending on the model, these conveyors can be used to transport various work pieces that can be either in free flow or fixed.

The most common applications for double conveyor models using timing belts are when transfers of pieces or pallets are required. For transport of small pieces, simple conveyors are used.

The models that use chain are ideally suited for the transport of metallic pieces with edges in bulk with the possibility of also incorporating support tooling for the step by step transport of the finished pieces.

Variants exist concerning the drive location, either located at the end or in central position. The different configurations can be observed in the diagram found in the annex.

NIKAI SYSTEMS conveyors, as is common knowledge, are totally modular and thus need no welding or other material finishes.

NIKAI SYSTEMS offers a wide range of joining elements that can be used for posterior extensions or for the installation of accessories such as guides, stoppers, photoelectric cells etc.

When the conveyor have 2 ways (for belt and chain), can be equiped with a width regulation systems and height regulation for load and unload process.

TOOTH BELT

Depending on the type of application, toothed belt conveyors have different configurations to fit the application requirements.

- Belt ways: It can have from 1 to several ways depending on the product to be transported.

- Drive: The belt can be placed in the extreme position (pulling or pushing) or in the central position, and can be placed at any point along the conveyor.

- Advancement: The direction of advance of the conveyor can be bidirectional or one-way.

- Belt:

- The belt can be suitable for working with or without accumulation.

- Belt width varies depending on application.

- Possibility of welding drive studs.

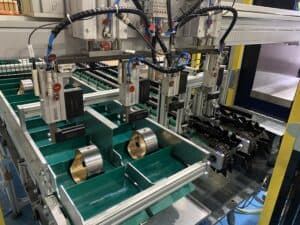

CHAIN

For processes where greater precision is required, chain conveyors with a step-by-step system are used. The use of chain gives us the advantage of using fins to tie the custom tools for the different references to be transported.

Generally, to guarantee positioning precision, gear motors with brakes are used to guarantee stopping during both loading and unloading (or both if the application requires it).

Another advantage of this system is the possibility of adding loading/unloading gantries to deliver the part to the loading or unloading system, such as: robots, cobots, gantries of the client's machinery. If, on the other hand, the process includes operators, it is protected in the forwarding parts.

Another advantage of this system is that it can work in environments with liquids, providing the conveyor with a tray for collection.