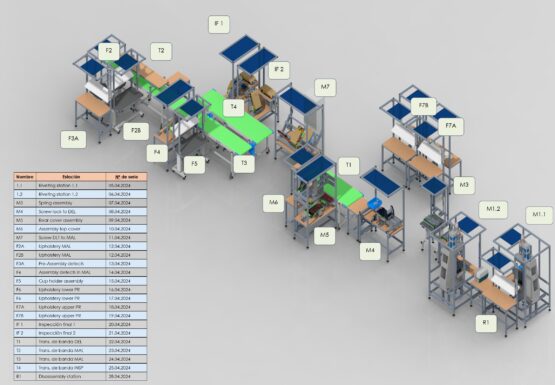

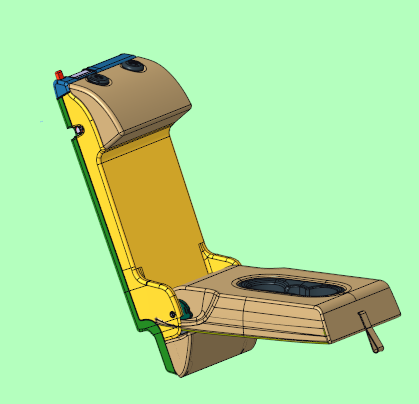

Automobile armrest assembly line

Rear armrest assembly line for automobiles. This line consists of independent stations, both manual and semi-automatic, for the assembly of the armrest.

The line is divided into 3 zones: DLE, MAL and Final Inspection.

GENERAL INFORMATION

- Dimensions of the product to convey: 400 x 260 x 80 mm

- Installation Tak-time: 46 seconds

WORKING STATIONS

DLE – Working station

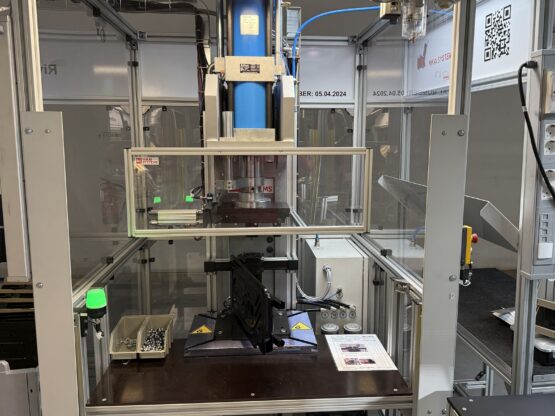

- M1.1 – Pressing station: Riveting of 2 rivets on each side.

- M1.2 – Pressing station: Riveting of 1 rivet on each side with vision station for checking rivets and assembling components. Includes QR traceability system

- M3 – Spring assembly: Checking riveting and assembling springs on both sides. Includes QR traceability system

- M4 – Screw the lock DLE: Checking springs, screwing the opening handle and placing the front trim. Includes QR traceability system

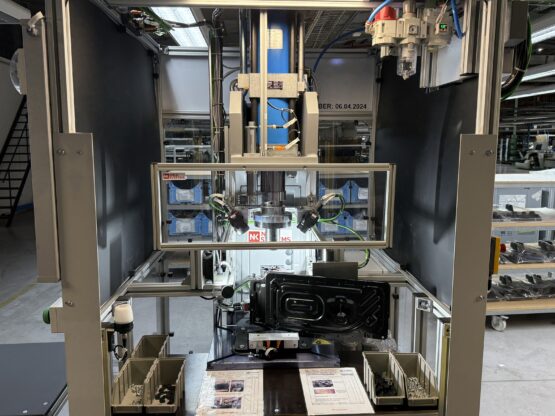

- M5 – Rear Cover assembly: Automatic clipping station and placing carpet.

- M6 – Assembly top cover: Assembly of trim and checking of part. Includes QR traceability system

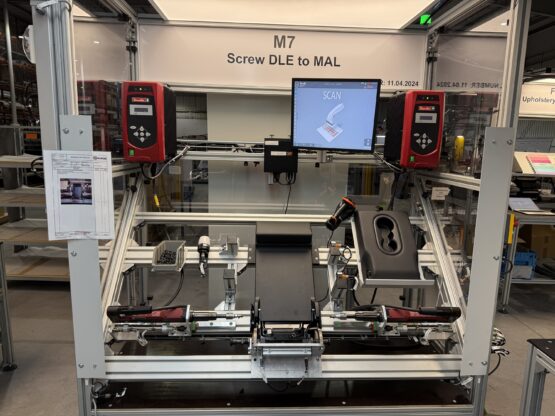

- M7 – Screw DLE to MAL: Semi-automatic screwing station with TORQUE control for joining the DLE to MAL assembly. Includes QR traceability system

MAL – Working station

- F2 + F3 – Pre-Assembly: Manual pre-assembly stations for components with height adjustment system for ergonomics.

- F4 – Assembly detects: Semi-automatic assembly station for pressing components together MAL

- F5 – Cup holder assembly: Assembly of cup holders.

- F6 – Upholstert lower PR: Pre-assembly station for mobile components for line compensation.

Final inspection. Working station

- IF 1 + IF 2 – Final inspection: Final inspection and checking station for the finished product. Includes QR traceability system.

All work stations are equipped with independent LED lighting, 220V power sockets, mains sockets, light switch, etc. The work stations are fed with parts by means of belt conveyors and/or individual work tables.

ELECTRIC CABINET

- SIEMENS PLC programming

- PROFINET frecuency inverters

- 12″ HMI SIEMENS touchscreen

- Remote control systems

FIELD INSTALLATION: ELECTRIC AND PNEUMATIC

- Inductive, magnetic detectors, photocells, etc.

- Signal distribution module

- Independent pneumatic field installation per workstation.

OTHERS

- Electric and mechanical desing

- Tooling integration. Brand: DESOUTTER

- Traceability of components per workstation.

- PC + screen in certain workstations.

INSTALLATION AND COMMISSIONING

- Assembly, installation, testing and commissioning at the client’s premises.

- Run and rate with the client

- Training of line personnel.