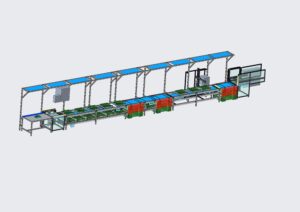

Machinery seat assembly line

CONVEYOR SYSTEM

- Accumulation roller chain conveyor (FMS). Model NT 820 26

- Working line

- Empty pallet pallet return (underneath working line)

- Multi-reference skid/WPC with 360º turn and 4 positions. Model NT 850 30

- Lifting and locating station for automatic workstation. Model NT 850 10

- Pneumatic stopper with dumpling

- Skid/WPC lifter. Model NT 600 40

- Automatic seat removal from pallet

- Working station with height regulation +/- 200 mm

- Working station with LED lighting, plugs, RJ45, etc.

- Inductive sensors, magnetics, photocells, etc.

- Signal distribution unit

- Pneumatic stoppers

- Pneumatic pallet lifters

- Seat removal

- Seat leak test

- Valve manifold

- PLC SIEMENS

- PROFINET frecuency inverter

- 12″ HMI CONFORT PANEL

- Remote control device

- RACK electric cabinet

- Mechanical and electrical desing

- Integration of the tools DESOUTTER

- Seating trazability

- PC and Screen in each working station

- Installation, testing and commissioning at client facilities.

Characteristics of the product to convey.

- Wight (seat + pallet + tooling): 120 kg

- Speed of the conveyor: 12 meters per minute (adjustable)

- Pallet dimensions: 700 x 700 mm

Accesories of the instalation

- Client staff formation

- Working station

- Line periferics

Layout