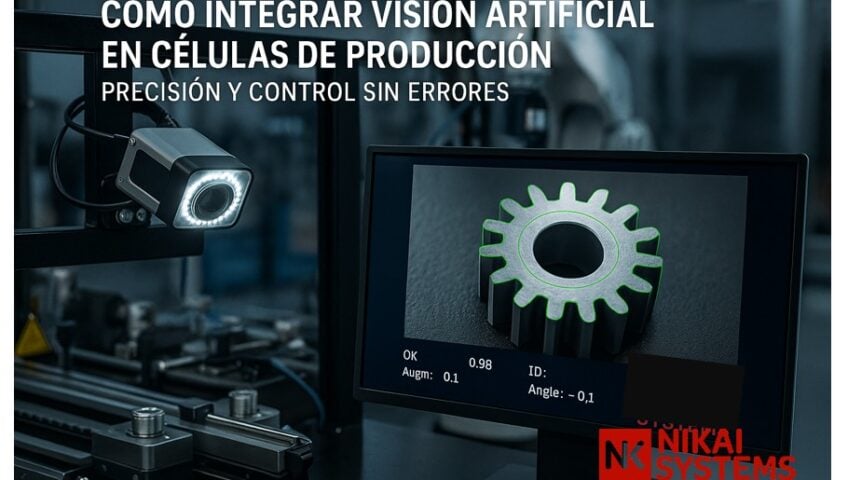

In today’s industry, where every second and every failure counts, machine vision has become an essential tool to guarantee quality, traceability and efficiency in production lines. Integrating these systems into automated cells is no longer an option, but a competitive advantage.

What is a production cell with machine vision?

A production cell is a station where specific tasks are performed automatically: assembly, verification, sorting… By incorporating a machine vision system (cameras, lighting, software and sensors), this cell can “see” and “decide” on the fly, without human intervention.

What is it used for?

- Quality inspection: detecting defects in parts, such as scratches, malformations or contamination.

- Dimensional verification: checking measurements and tolerances in real time.

- Code reading: automatic scanning of QR, Datamatrix or bar codes (1D/2D).

- Orientation and positioning: guide robots or manipulators according to the real position of the part.

- Automatic rejection: separate defective products without stopping the line.

What is needed to integrate it?

- A suitable optical system (industrial camera, lens and lighting system).

- Specialised software to process the images and generate automatic decisions.

- An interface to the PLC or line control system.

- Mechanical design and installation in the cell adapted to the application and working conditions.

At NIKAI SYSTEMS S.L. we design and integrate customised vision solutions for our customers, whether for final control cells, sorting stations or assembly processes. Our experience allows us to select the right equipment (lenses, cameras, filters, lights) and optimise integration with existing automation.

Write a Comment