Choosing the right gear motor is a critical decision when designing an assembly line. An incorrectly sized gear motor can cause overheating, premature failure or loss of performance, while an oversized one represents an unnecessary expense.

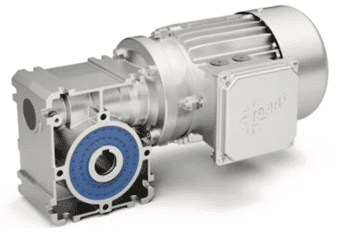

At NIKAI SYSTEMS, we routinely rely on NORD gear motors because of the advantages they offer in industrial applications. Their modular design allows for precise combinations of reduction ratio, power and gear type (coaxial, parallel shaft, bevel, etc.), adjusting to the exact requirements of each line.

In addition, their monoblock housings ensure rigidity and precision, minimising backlash and vibrations that affect the service life of the system. NORD gear motors achieve very high efficiencies even at extreme reduction ratios and withstand demanding axial and radial loads.

To amortise the investment, a good gear motor must operate with constant efficiency, avoid frequent maintenance and offer slow performance degradation. In our lines, a well-selected gear motor can make all the difference in operating cost, reliability and return on investment.

That is why, in every project we develop, we listen to the customer’s requirements (load, speed, environment, service life) and select the appropriate gear motor, working with reliable brands such as NORD, so that the line will operate accurately for years to come.

Write a Comment