Logistic shorter for packaging

Turnkey project for a logistic shorter for packaging

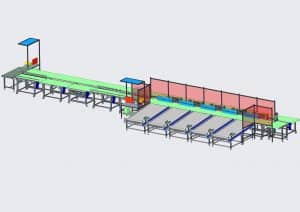

Layout

Scope of supply:

Conveyor systems

- Belt conveyor. Model NT 100

- Belt conveyor with extreme gearmotor

- Belt conveyor with central gearmotor (bidireccional)

- Roller conveyor. Model NT 200

- Roller conveyor

CONTROL STATION

- Belt conveyor equipped with weighing machine

- Package measurement system

- Barcode reader (5 faces) for destination assignment

ELECTRIC FIELD INSTALLATION

- Photocells

- Magnetic detectors

- Signal distribution unit

PNEUMATIC FIELD INSTALLATION

- Pneumatic deviator

ELECTRIC CABINET

- SIEMENS PLC Programming

- Frecuency inverter for gearmotors

- SIEMENS HMI 12″ touchscreen

- Remote control systems

- SMART-SERVER

- Bus: PROFINET

ACCESORIES

- Working station with LED lighting, plugs, etc.

- Picking table

- Label printers

INSTALLATION AND COMMISSIONING

- Assembly, installation, testing and commissioning at the customer’s facilities in Italy.

Characteristics of the product to convey

- Packaging: From 1 to 50 kg

- Size: From envelopes to packages up to 1m³

Others

- Client staff training