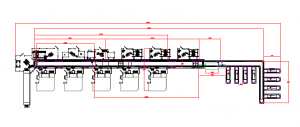

Machining assembly line

Automation of a machining line for different automobile components.

Models used

Cardan chain conveyor. NT 900

- NT 910 20 – Double drive unit.

- NT 950 11 – Positioning and elevating station.

- NT 950 20 – Pneumatic sttoppers.

- NT 950 50 – Diverters between lines.

- NT 950 60 – Pallet recirculation disc.

- NT 950 55 – 90º turn/curve

- NT 950 60 – 180º turn/curve

Manufacturing and installation of a assembly line of cardan chain, the pallets cross through the different stations (loading, unloading, machining, washing, inspection and laser stations)

The assembly line consists of: main line, recirculation line, loading and unloading islands.

Characteristics of the product to convey

-

- Pallet: 520 x 220 mm

- Quantity: 5 different references

- Weight: 10 Kg (skid + tooling + piece)

Layout